OUR COMPANY

Home-Style Bricks, Rib and Blocks has a long history of more than half a decade of supply to the building sector. Home-Style Bricks, Ribs and Blocks is a member of the Construction Industry federation of Zimbabwe, collectively servicing the civil, building, and engineering sectors. Our premises occupy some 70000 sqm, and based in Harare, Zimbabwe we are well situated to service the Harare, and all other markets. Our quality product has been used nationwide, and we are also capable of exporting to many of the countries in the Southern African Region. Our product is suitable for all types of building where the following is required: suspended flooring, suspended concrete slabs, concrete flooring, casting concrete slabs, construction of slabs and installing concrete slabs. Materials can be assembled by hand and use damp coursing on walls before casting concrete floors

OUR PRODUCT

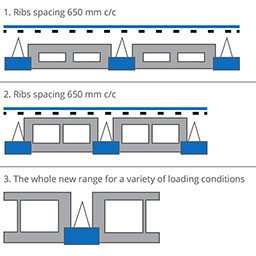

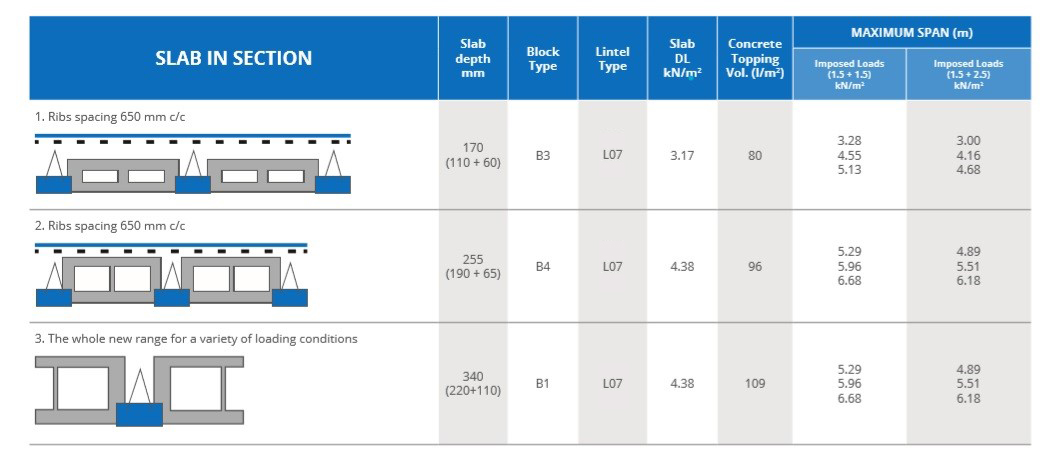

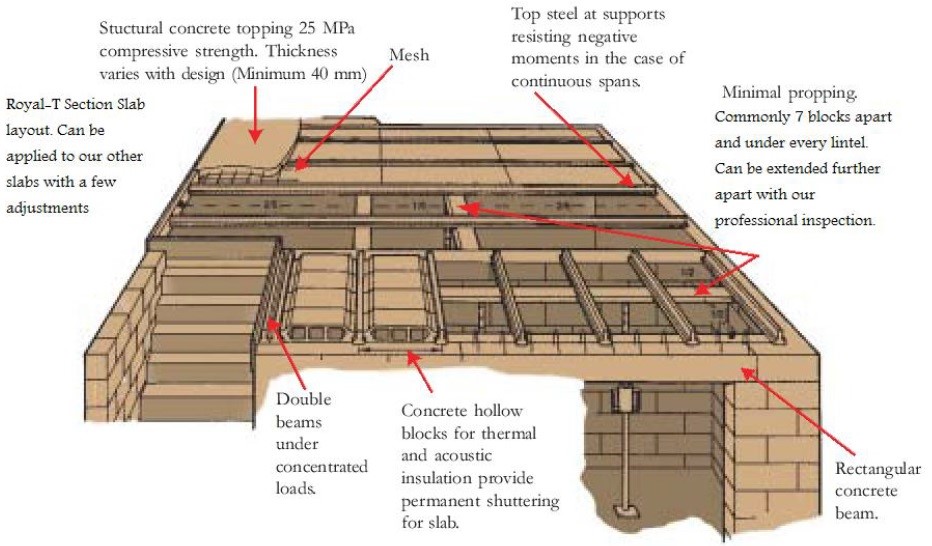

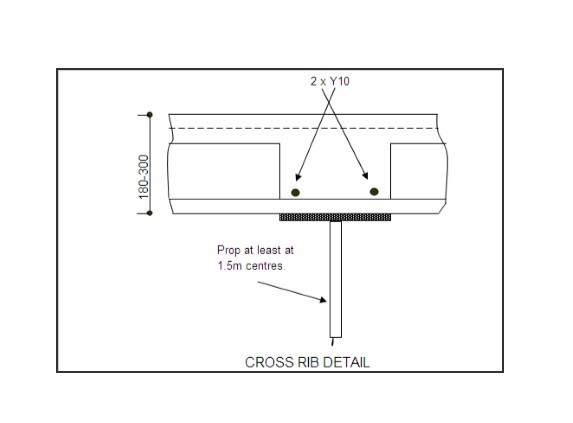

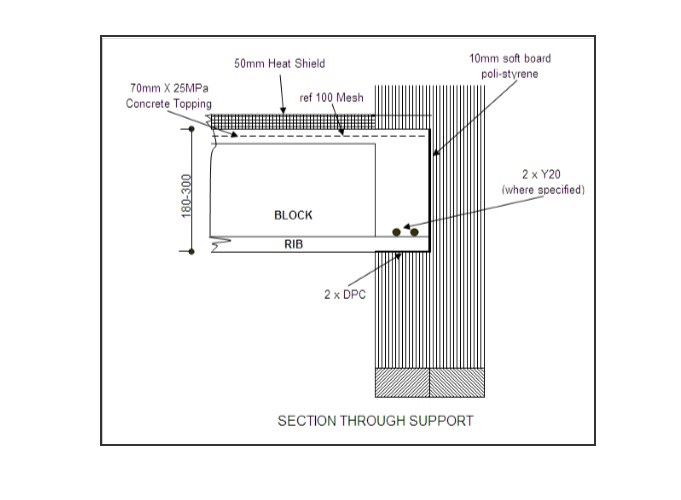

Home-Style Bricks, Rib and Blocks is the trademark of our highly economical suspended flooring system. The two-part system, consisting of ‘ribs’ and ‘blocks’, forms permanent shutters for the quick and economical construction of floors in multi-story buildings. The ‘Ribs’ or Lintels: these are reinforced with two Y16 deformed bars that are used to span between walls. The reinforcing steel is in the form of a lattice, protruding positively from the concrete to strengthen the lintel for transport, as well as to supply shear strength in the floor. The lattice is tied-in to steel mesh and other before casting of concrete. The ‘Blocks’ are hollow section precast units, placed to span the ribs, thus completing the shutter. Thesteel lattices are tied to S100 steel mesh and other supporting structural components, and the floor is cast in–situ with concrete. With this innovative Rib and Block system, we can assist with the following economical building solutions: suspended flooring, suspended concrete slabs, concrete flooring, casting concrete slabs, construction of slabs and installing concrete slabs

ADVANTAGES

Suitable for applications in all types of buildings where suspended floors are required.

- The system is ideal for residential houses in particular.

- Rib and Block slabs are quicker and less costly to build than traditional shuttered concrete.

- Ideal composite action between lattice lintels and cast-in-situ concrete, optimising strength/material requirements for cost savings.

- The best solution for complicated in shape slabs with skylight openings, cantilevers etc.

- Simple and quick to install even with unskilled labour.

- Highly competitive price and a large stockholding of standard items ensures short delivery times.

- Rib and Block slabs are assembled by hand – no cranes or other machinery required. Hollow core slabs are very heavy and require cranes for assembly.

INSTALLATION

PRECAST RIB AND BLOCK SOLUTIONS • ECONOMICAL SUSPENDED FLOORING • SUSPENDED SLABS • CONCRETE FLOORS

OUR 6 STEP INSTALLATION PROCESS